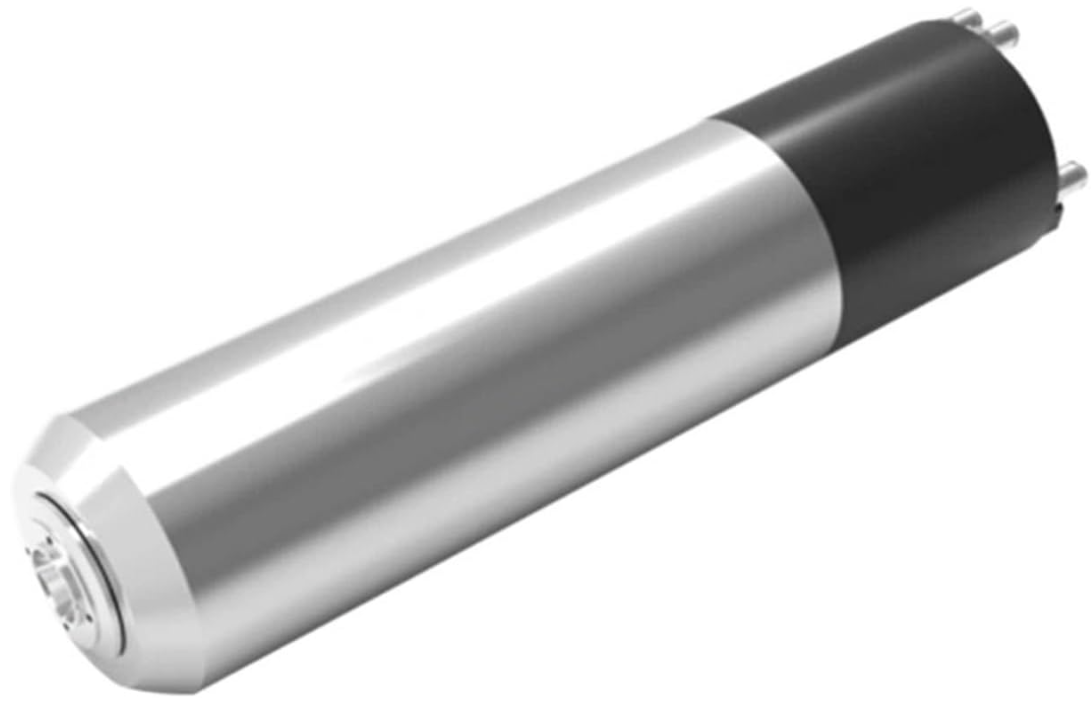

If you’ve ever worked with CNC machines, you know that precision and efficiency are key. After taking on several projects that required precise milling, drilling, and cutting, I decided to upgrade my setup. I came across the GDL150-40-12Z Cooling Spindle with an Automatic Tool Changer on Amazon, and it seemed like the perfect addition to my workshop. Here’s an in-depth look at my experience using this spindle, from installation to performance, as well as the pros and cons I’ve encountered along the way.

First Impressions and Installation

When I first started working with CNC machines, tool changes felt like a slow and clunky process. I often had to manually swap out bits, which took up a lot of time, especially on larger projects. The idea of an automatic tool changer immediately appealed to me because it would allow for seamless transitions between different operations.

Setting up the spindle wasn’t as intimidating as I had expected. I followed the manual carefully, and everything was laid out in a way that made sense. The spindle attached to my CNC frame with little effort, and connecting the cooling system was a breeze as well. What stood out to me during the installation was how compact the spindle felt compared to other models I had used in the past, even though it packs a powerful punch.

I did take my time during the setup, making sure everything was securely in place, and that the cooling lines were properly installed to avoid overheating during use. The spindle comes with a built-in cooling system, which uses water to keep the temperature down, and it runs quietly, even when the spindle is working at full speed.

Building Experience: Putting the GDL150-40-12Z to the Test

I was eager to see how the spindle performed in a real-world setting. So, I dove into a few different projects to fully explore its capabilities. From cutting intricate designs into wood to working with aluminum, this tool really delivered.

Project 1: Wooden Signs for a Home Renovation

For my first project with the GDL150-40-12Z, I decided to make custom wooden signs for a home renovation project I was working on. This involved engraving text and fine details into oak and pine. The automatic tool changer allowed me to switch between different bits without having to stop the machine. I could go from rough cuts to fine detailing in no time at all.

The spindle maintained excellent precision, and the cuts were incredibly clean. Even when working with hardwoods like oak, the spindle didn’t struggle or slow down. The cooling system really came in handy here, as it kept the spindle at a consistent temperature, preventing overheating during long runs.

One thing that really surprised me was how quiet the spindle was, even while working at high speeds. This made it much easier to focus on the task at hand without being distracted by loud noises. Plus, since the spindle doesn’t vibrate much, I could keep a steady hand and achieve the precision I needed for fine details.

Project 2: Aluminum Parts for a DIY CNC Build

Next, I moved on to a more challenging material: aluminum. I needed to cut some brackets and small parts for a DIY CNC build I was working on. I wasn’t sure how well the spindle would handle metal, but it exceeded my expectations.

I used a variety of bits for this project, including end mills for cutting and drill bits for boring holes. The tool changer worked flawlessly, swapping out tools in a matter of seconds. I didn’t have to babysit the machine, which gave me time to prepare for the next steps in the project while the CNC did its thing.

The spindle cut through the aluminum with ease. I didn’t notice any signs of stress or overheating, thanks to the cooling system. The cuts were smooth, and I didn’t have to deal with any burrs or rough edges. Overall, it made quick work of the aluminum parts, saving me a lot of time compared to my old setup.

Project 3: Engraving Acrylic Panels

For the final test, I wanted to see how well the spindle would handle engraving on acrylic panels. I’ve had issues with acrylic melting or chipping in the past, so I was curious to see if this spindle could manage the job. I chose a fine engraving bit and set the machine to a lower speed to avoid melting the plastic.

The results were fantastic. The spindle operated smoothly, and I didn’t experience any melting or warping of the acrylic. The precision of the engravings was top-notch, and I was able to achieve the exact depth I wanted without any issues. The tool changer again made things simple, allowing me to swap to a different bit to finish off the edges of the panels.

Pros of the GDL150-40-12Z Automatic Tool Changer Spindle

1. Seamless Automatic Tool Changes

One of the biggest advantages of this spindle is the automatic tool changer. It eliminates the need for manual tool swaps, saving time and effort, especially during multi-step processes. This feature alone increased my productivity and made my workflow much more efficient.

2. Excellent Cooling System

The built-in water-cooling system keeps the spindle at a consistent temperature, even during long runs or when working with tougher materials like metal. This not only extends the life of the spindle but also ensures consistent performance without the risk of overheating.

3. High Precision and Stability

This spindle excels in precision, delivering clean, accurate cuts across various materials. Whether I was engraving wood, cutting metal, or working with acrylic, the spindle maintained consistent speed and precision without wobbling or vibrating.

4. Versatility Across Materials

The spindle can handle a wide range of materials, from wood and acrylic to metal. This versatility means I can use it on multiple projects without needing to switch between different tools or spindles. It’s truly an all-in-one solution for my CNC machine.

5. Quiet Operation

One thing that stood out to me was how quiet this spindle runs compared to others I’ve used. Even at high speeds, the noise level was low, making it easier to work in the shop without needing ear protection.

Cons of the GDL150-40-12Z Automatic Tool Changer Spindle

1. Higher Initial Investment

The spindle is more expensive than basic models, but considering its features, it’s a solid investment for serious CNC users. If you’re just starting out, the price might feel steep, but the time and hassle it saves in the long run are worth it.

2. Requires Careful Setup

The installation process isn’t overly complicated, but it does require attention to detail, especially when setting up the cooling system. If you’re not familiar with CNC setups, you might need to spend extra time ensuring everything is connected and working properly.

3. Learning Curve for the Tool Changer

The automatic tool changer is a fantastic feature, but it does take some time to get used to. I found myself needing to double-check the tool settings initially, as I was still adjusting to the new system. After a few projects, though, it became second nature.

FAQs

1. Is the spindle compatible with all CNC machines?

The spindle is compatible with most CNC machines, but you’ll want to check the specifications of your machine to ensure proper fit. It’s designed to work with standard mounts and cooling systems, so installation shouldn’t be an issue for most setups.

2. Does the spindle come with all necessary parts?

Yes, the spindle comes with the necessary components, including the cooling system and the automatic tool changer. However, depending on your CNC setup, you may need additional hoses or adapters for the cooling system.

3. How long can the spindle run without overheating?

The spindle can run for extended periods without overheating, thanks to the water-cooling system. I’ve used it on multi-hour projects without any issues, and the cooling system has kept the spindle at a consistent temperature throughout.

4. What materials can I use with this spindle?

This spindle can handle a variety of materials, including wood, aluminum, acrylic, and other metals. Its versatility makes it suitable for a wide range of projects, from intricate engravings to heavy-duty cutting.

5. Is the tool changer reliable?

Yes, the automatic tool changer has been reliable in my experience. It swaps out tools quickly and securely, allowing for smooth transitions between different tasks. It took a little getting used to, but once I had everything set up, it worked flawlessly.

6. How loud is the spindle during operation?

The spindle operates quietly compared to other CNC spindles. Even at higher speeds, the noise level is manageable, and you can work comfortably without the need for ear protection.

7. Is the spindle suitable for beginners?

While the spindle is easy to use, it’s more suitable for users who have some experience with CNC machines. The setup and tool changer system require some familiarity with CNC operation, so beginners might find it challenging at first.

Final Thoughts

After spending a good amount of time using the GDL150-40-12Z Automatic Tool Changer Spindle, I can confidently say that it’s a game-changer for CNC enthusiasts. The automatic tool changer alone makes a significant difference in how quickly and efficiently I can complete projects. Combined with the precision, cooling system, and versatility, this spindle has become an essential part of my workshop.

It’s perfect for anyone looking to save time and effort on CNC projects without compromising on quality. Whether you’re working with wood, metal, or acrylic, this spindle delivers consistent, reliable results across the board. If you’re ready to take your CNC work to the next level, this tool is definitely worth considering.

Buy it here on Amazon